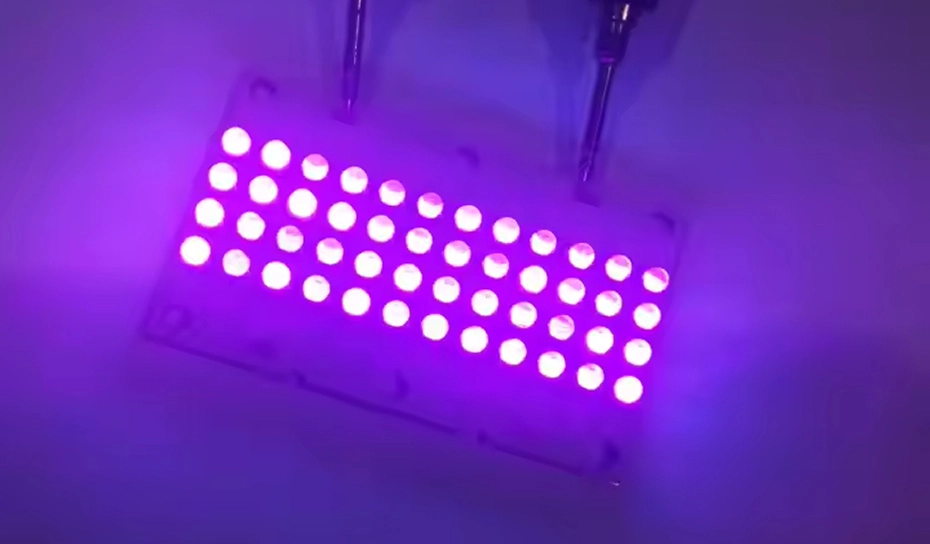

Precision UV LED Solutions for Global Industries From Curing to Inspection

Innovative UV LED Solutions for Precision Curing, Inspection, and Sterilization

Trusted by Global Leaders in Electronics, Automotive, and Medical Industries

60+ Countries Served | ISO 9001 Certified | CE & UL Approved

Mercury-Free & Eco-Friendly Technology

About UVET

Dongguan UVET Co., Ltd. established in 2009, specializes in designing, developing, and producing UV LED curing system and UV LED inspection light sources.

-

2009

since

-

3000+

Systems

-

60+

countries

-

30+

partners

Tailored UV LED Solutions

Dongguan UVET Co., Ltd. established in 2009, specializes in designing, developing, and producing UV LED curing system and UV LED inspection light sources.

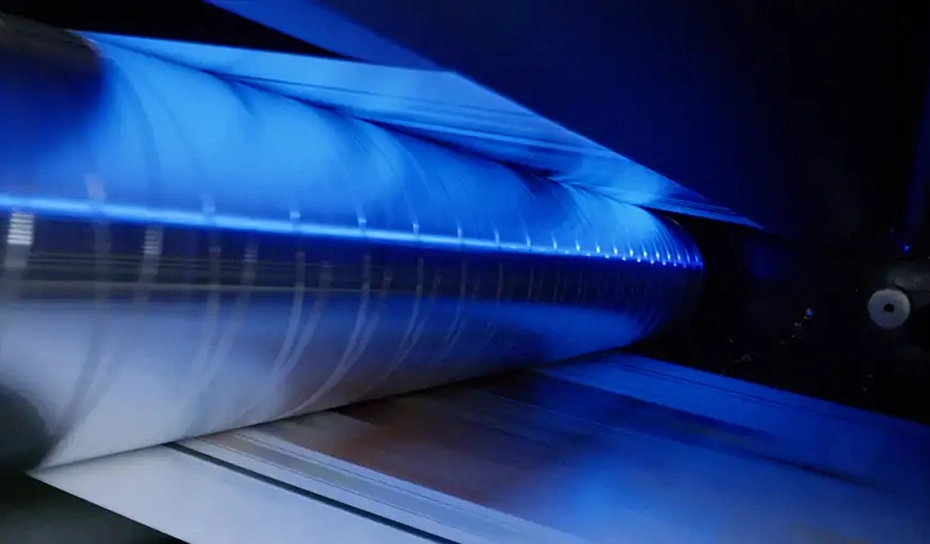

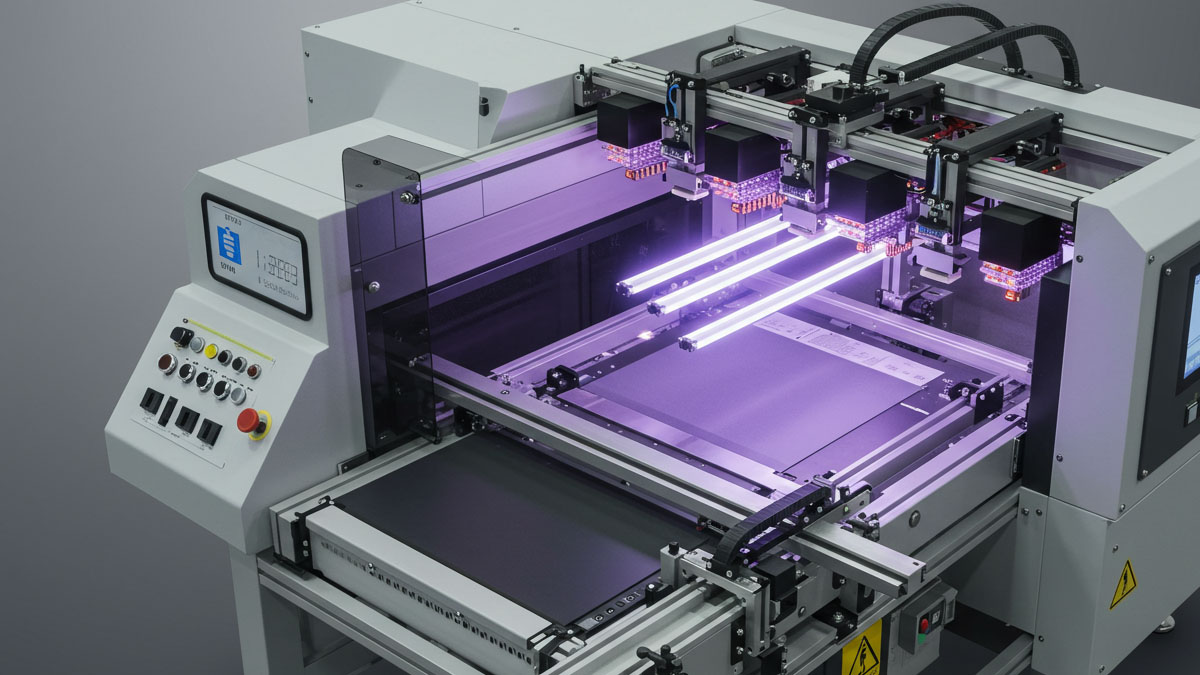

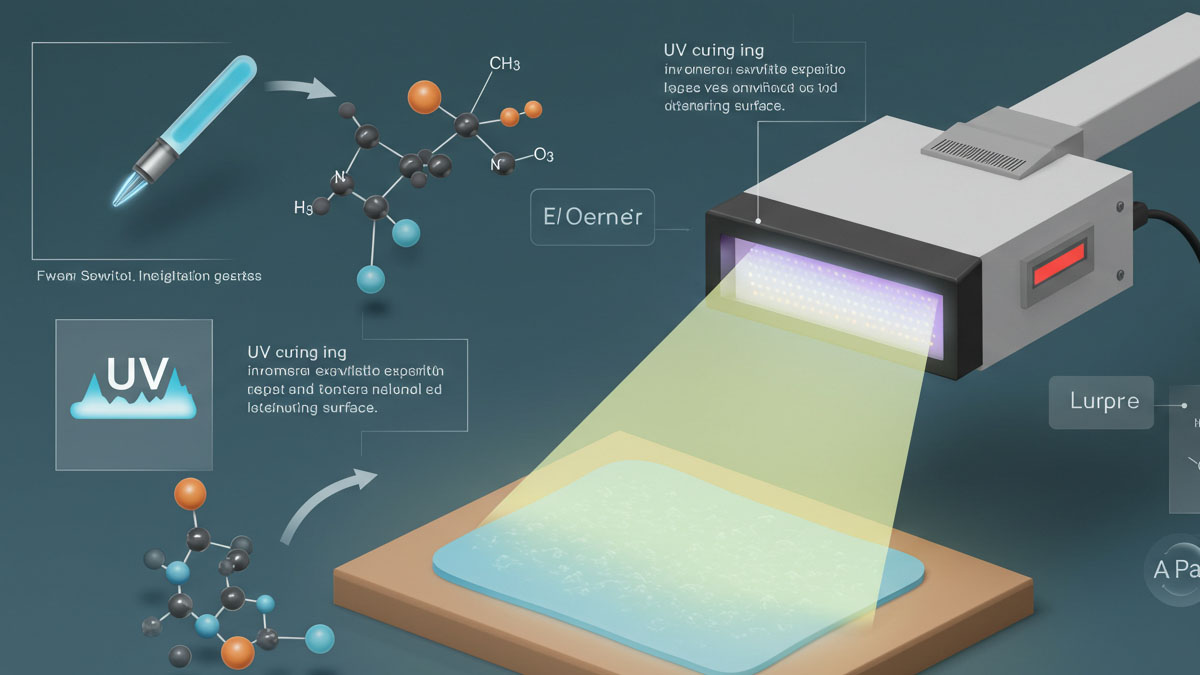

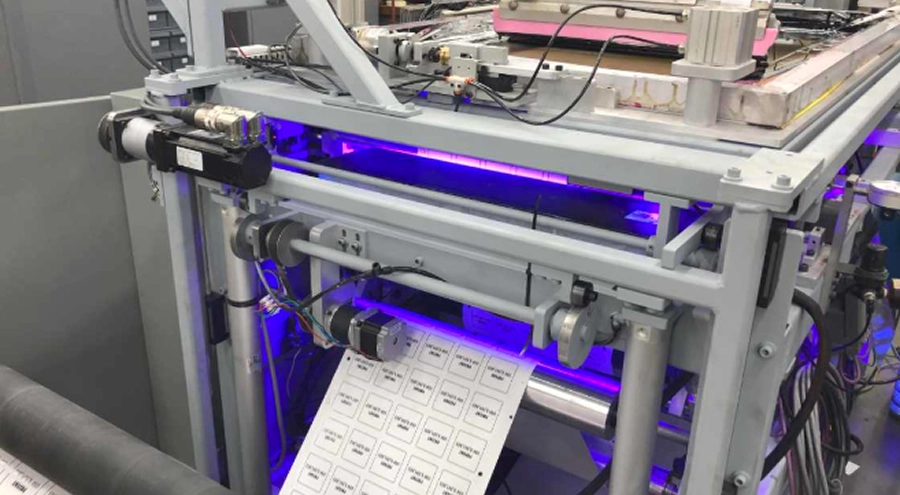

UV Printing - A Detailed Guide

What is UV Printing? UV (Ultraviolet) printing is one of the most developed digital and UV printing technologies, in particular, saving time and energy by 60% by curing or drying inks, coatings, or varnishes employing UV light throughout the printing process. Unlike past methods, which use heating or hot air-assisted drying, UV printing utilizes UV inks that are kept in liquid form until contact with the UV LED light is made, at which point they are instantly cured or hardened. The technology is eco-friendly while also yielding faster production rates, higher quality prints, and improved durability. It is extensively adopted across a plethora of sectors such as packaging, signage, electronics, labels, and promotional materials. Ideal for offset, flexo, and inkjet printing. Features of UV Printing Applications of UV Printing The distinct features and flexibility of UV printing technology make it useful in a variety of fields, including: • Signage and Displays: Preparing outdoor and indoor signs, banners, posters, exhibition graphics, and point-of-sale displays that are scratch-resistant and long-lasting. • Packaging: Directly printing onto the packaging materials like cardboard, plastics, and glass for product boxes, bottles, and containers. UV LED for Printing • Promotional Products: Logo and design application on a diverse ...

Learn More

UV LED for Medical Devices: The Ultimate Guide 2025

UV LED for medical devices denotes a photochemical process in which light-emitting diodes (LEDs) emit ultraviolet (UV) rays of light at specific frequencies. In the medical field, this technology is used for two primary reasons: UVC LEDs at 275 nanometers can inactivate viruses, bacteria, and other microorganisms from the external surfaces of surgical instruments, medical tools, and laboratory equipment. UVC LED sterilization does not use heat or chemicals, unlike traditional methods, which makes it non-toxic, instantaneous, and residue-free, resulting in enhanced sterilization effectiveness. This renders it safe for sensitive environments such as operating rooms or cleanrooms. Medical-grade adhesives used for bonding surgical tools, catheters, syringes, and implants require curing without losing biocompatibility. Bonds formed using 365-nanometer UV LED systems emit supremely hazardous by-products during curing, thus ensuring biocompatibility. What Makes UV LED Curing Significant in Medical Device Manufacturing? Precision, cleanliness, and reliability are essential in the healthcare industry, which is highly regulated. Here’s what makes UV LED curing important: Traditional curing and sterilization methods generate considerable heat that can easily damage plastics, polymers, and delicate electronic parts within medical devices. Unlike other methods, UV LED curing preserves sensitive structures and devices because its curing processes maintain low temperatures. UVC LED ...

Learn More

UV LED for Automotive: Advanced & Efficient Solutions

UV LED for Automotive Cures headlight coatings, dashboard adhesives, and EV battery seals with low heat to prevent substrate damage. Enhances durability in extreme temperatures. What is UV LED Curing? UV LED for automotive refers to the process of curing (drying or hardening) coatings, inks, adhesives, and sealants using light emanating from diodes (LEDs) to ultraviolet (UV) light. Compared to traditional mercury UV lamps, UV LED systems operate at lower temperatures, consume less energy, and have more precise output at specific wavelengths. These benefits are ideal for sensitive substrates and for complex automotive applications. Key Applications in the Automotive Industry We have adopted UV LED curing technology in numerous processes throughout automotive manufacturing. Applications requiring low heat and high-strength bonding take the most advantage of it. Key applications are listed below: 1. Headlight Coating Curing UV LED systems cure anti-fog and protective coatings on polycarbonate headlight lenses. These coatings assist with clarity enhancement, durability, resistance to UV, and elongation to break. Manufacturers can apply UV LED curing to improve production speeds and ensure uniform finishing without the adverse effects of warping heat-sensitive plastic parts. 2. Dashboard Adhesive Bonding Dashboards today are made out of multi-material assemblies. UV LED curing, absorbs ...

Learn More

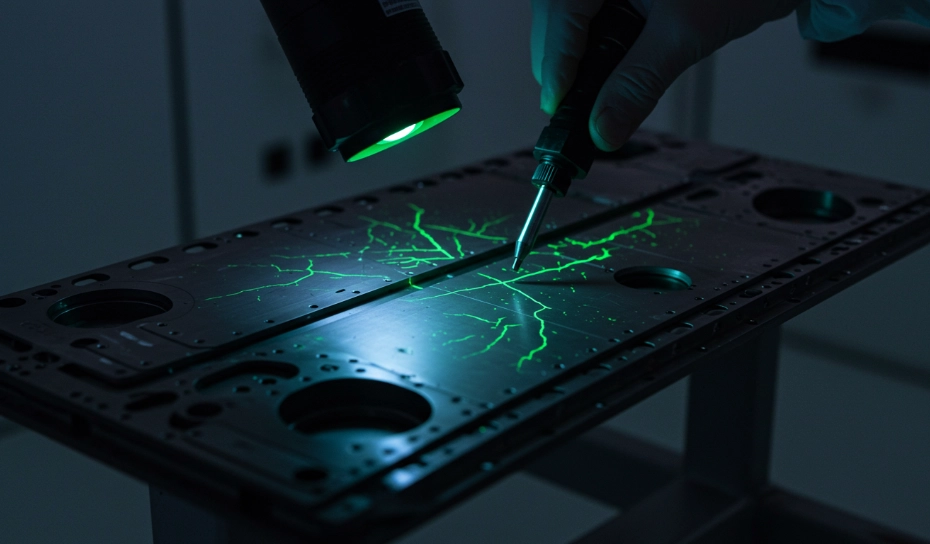

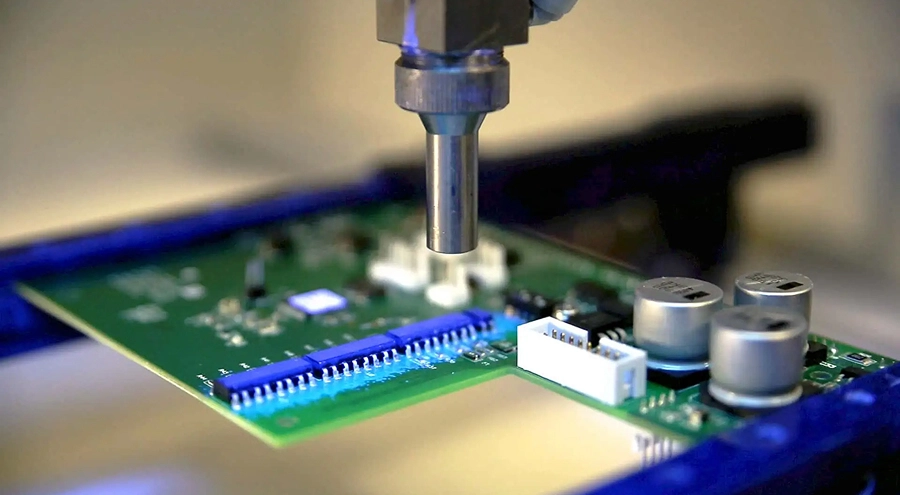

UV LED for Electronics Application: Why it’s Critical

UV LED curing is the technique of curing adhesives, coatings, and encapsulants using the ultraviolet light emitted from LEDs. In the manufacturing of electronics, this technique is useful for instant photo degradation of materials without exposing a great deal of heat to components, which is a concern for delicate parts. In comparison to generic mercury UV lamps, UV LED systems provide: ° Strictures for use during diagnosis or surgery. ° Environmentally friendly technology. ° Process temperature that does not damage components. ° Uniform temperature distribution via rapid cooling features. ° Curing methods that utilize barrier materials such as UV filters during the treatment stage. ° On/Off switching for enhanced energy savings. Why it Critical in Electronics Manufacturing? Enclosures for modern electronics usually have fine pitch, soft, and easily warped chips. Integrated circuits also combine a large number of highly miniaturized parts mounted on the surface. These components are highly sensitive to temperature, pressure, and other forms of mechanical or thermal stress. Conventional curing techniques using thermal ovens or mercury UV lamps achieve high rates of curing, but run the risk of overheating delicate chips, which can result in warping, damage, or even permanent failure. These problems are solved through low-temperature, ...

Learn More

Explore Our Expertise

From Case Studies to Technical Support,

We’ve Got You Covered.

Our resource library encompasses solutions across various fields, including:

- Case Studies

- Technical FAQs

- OEM Solutions

And they are all available for free.